As a leading manufacturer in Hungary, PARTIUM ’70 Co. Ltd. has been supplying wide films to its customers. The product family TVK HELIOFOL combines the results of long years of production experience and a consistent development motivated by customers requirements.The wide product range enables the customers to choose the grades best fitting their specific applications.

The top quality of TVK HELIOFOL films are based upon a continuous quality control and secured by a certified ISO 9001 Quality Assurance System in place.

TVK HELIOFOL films have the following properties:

TVK HELIOFOL wide films family comprises the following product groups:

TVK HELIOFOL greenhouse films excel with their high flexibility, tensile strength and weather resistance. Multi-layer film grades containing specific additives to suit particular applications provide optimal conditions for the growing of various plant cultures.

TVK HELIOFOL mulch films provide the best posible conditions for cultivated plants by increasing soil temperature, retaining humidity and preventing weeds from growing. When applied as soil covers, they can reduce herbicide consumption in plant growing and offer special advantages for bio-gardening.

Owing to their multi-layer structure, TVK HELIOFOL silage films successfully combine the favourable properties of individual layers. By preventing the effects of sunshine and air, they provide optimal conditions for the lactic fermentation of silage and preserve vitamins and nutrients for prolonged period of time.

TVK HELIOFOL general covering films are recommended for general covering purposes, producing mainly from recycled polyetylene, in black colour or Unqualified colour.

TVK HELIOFOL building film when used to cover construction materials, such as concrete, wood, bricks, etc., can significantly reduce losses due to elements. Temporary facilities and protected job sites can quickly and relatively cheaply be made from TVK-Heliofol building film. This way, almost any work can be done irrespective of weather. When large areas are concreted, the concrete is continuously kept wet in order to prevent it from getting desiccated and from cracking due to desiccation. It is more practical and less labor consuming to protect the wet concrete with a TVK-heliofol building film cover.

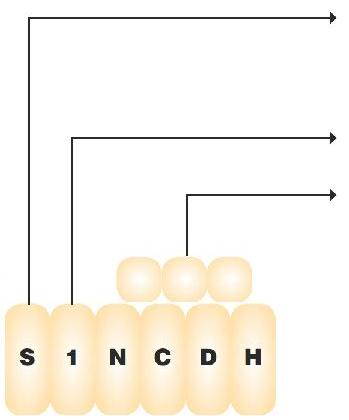

Letter code for application:

S – greenhouse film

T – mulch film

Q – silage film

UV resistance in years

Letter code for properties.

See explanation in the Selection Guide.

Example: Clear film UV stabilized for 1 year, with antifog and light diffusion additives increased heat retaining properties: S1BCDH

Grade Code | Properties | Recommended Application |

S0N | Clear film with excellent light transmission, without UV stabiliser. | Short term greenhouse film. It can be used for 6 months when put up in October. |

S1N S2N S3N | Clear film UV stabilised for 1, 2 or 3 years, with excellent ligth transmission. Films stabilised for 2 or 3 years have in increased resistance against herbicides. | General purpose greenhouse film. Due to a gradual deposit of dirt on their surfaces, films stabilised for 2 or 3 years will loose 15-20% of light trasmission from the second year of use on. The loss of light transmission may cause light demanding plants to reduce yield to the same extent in winter. |

S1NC S2NC | Theree-layer clear film stabilised for 1 or 2 years, with execellent light transmission, containing antifrog additive. | Greenhouse film recommended for light demanding plants sensitive to dripping water and fungi. |

S1ND S2ND S3ND S4ND | Clear film stabilised for 1, 2 or 3 years with a special light diffuser. The additive diffuses ligth so than a shadow free and even light distribution is achieved in any part of the greenhouse without reducing the amount of penetrating light. | General purpose greenhouse film for higher yields. Due to its good heat retention, it saves energy in heated greenhouses. It reduces the risks of burning by diffusing the strong sunshine in summer and increases the amount of useful light in winter. Due to a graudal deposit of dirt on their sufaces, films stabilised for 2 or 3 years will loose 15-20% of light transmission may cause light demanding plants to reduce yield to the same extent in winter. |

S1NCD S2NCD | Clear film stabilised for 1 or 2 yaers, combining light diffusion and antifog properties. | It is recommended for growing plants sensitive to dripping water and fungi and for achieving higher yields. It combimes the favourable properties of films containing light diffusioning or antifog additives. |

S1NH S2NH S3NH | Thee-layer clear film stabilised for 1,2 or 3 years with increased heat retention. Its special raw material and structure produce higher than usual temperature inside the greenhouse. | It is particularly applicable for winter use. The higher greenhouse temperature reduces the risks of frost damage and saves energy. Due to a gradual deposit of dirt on their surfaces , films stabilised for 2 or 3 years will loose 15-20% of light transmission from the second year of use on. The loss of light transmission may cause light demanding plants to reduce yield to the same exent in winter. |

S1NCH S2NCH | There-layer clear film stabilised for 1 or 2 years, containing antifog additive, with increased heat retention. | It is recommended for winter growing of plants sensitive to dripping water and fungi. It combines the properties of antifog and higher greenhouse temperature. |

S1NDH S2NDH S3NDH | There-layer clear film stabilised for 1, 2 or 3 years, containing a light diffusion additive, with increased heat retention. | It combines the advantages os light diffusion and heat retention. It secures higher avarage yield and saves energy in winter. In reduces the risks of frost damage. Due to a graudal deposit of dir on their surfaces, films stabiled for 2 os 3 years will loose 15-20% of light transmission from the second year of use on. The loss of light transmission may cause light demanding plants to reduce yield to the same extent in winter. |

S1NCDH S2NCDH | Three-layer clear film stabilised for 1 or 2 years, with light diffusion and antifog additives and increased heat retention. | It is recommended for growing plants sensitive to driping water, strong sunshine and fungi. It reduces the risks of frost and saves energy increasing yield. It combines antifog and light diffusing properties and the advantages of higher heat retention. |

S0B | Clear film with execellent light transmission and without UV stabiliser. | Inner film of greenhouses for short term applications. It impoves heat insulation, reduces the risks of frost and saves energy in greenhouses. |

S1B | Clear film UV stabilised for one year, with excellent light transmission. | It can be used as an inner film of greenhouses for one years use. It impoves heat insulation, reduces the risks of frost and saves energy in greenhouses. |

S1BC | Clear film UV stabilised for one year, containing antifog additive. | It is recommended as an inner film of greenhouses for plants sensitive to dripping water and fungi. It impoves heat insulation, reduces the risks of frost and saves energy in greenhouses. |

S1BD | Clear film UV stabilised for one year, containing light diffusion additive. | As an inner film of greenhouses, it is recommended for plants sesitive to strong sunshine. It improves heat insulation, reduces the risks of frost and saves energy in greenhouses. |

S1BCD | Clear film UV stabilised for one year, containing light diffusion and antifog additives. | As an inner film of greenhouses, it is recommended for plants sensitive to strong sunshine and fungi. It improves heat insulation, reduces the risks of frost and saves energy in greenhouses. |

S1F S2F | Black, non transparent film, UV stabilised for 1 or 2 years. | It is recommended for special mushroom growing greenhouses and for poultry raising tents (turkey, geese, pheasants). |

S1FW S2FW | Non transparent film UV stabilised for 1 or 2 years, with a white outer and a black inner side. | It is recommended for special mushroom growing greenhouses and for poultry raising tents (turkey, grrse, pheasants. The white outer layer reflects a part of the sunshine, therefore the greenhouse or tent has a lower temperature inside than those made of all black films do. |

T0MN | Clear mulch film without UV stabiliser. | Due to its greenhouse effect, this film secures a higher soil temperature and prevents evaporation when used as a soil cover. |

T0MF | Black, non transparent film whithout UV stabiliser. | When used on the soil, it warms up and keeps the soil underneath warm. It prevents the soil from drying up. By preventing light transmission, it prevents weeks from growwing. Its application also reduces herbicide consumption. |

T0MZ | Translucent, greenish mulch film with a special light selective additive and without UV stabiliser. | It provides ideal conditions for the development of useful plants and considerably prevents weeds from growing. Its application greatly reduces herbicide needs. |

T0AF | Black soil film for general purposes without UV stabiliser. | For general applications, such as covers for the temporary protection of fodder, building materials, etc. |

Q1F | Three-layer black, non transparent silage film UV stabilised for one year. | It is recommended to cover and protect fodder silos. It secures optimal conditions for the longterm preservation of vitamins and nutrients. |

Q1W | Three-layer white silage film UV stabilised for one year. | It is recommended to cover and protect fodder silos. The white film reflects the most part of the light, securing a lower temperature underneath. |

Q1WF | Three-layer non transparent silage film with black and white sides, UV stabilised for one year. | It is recommended to cover and protect fodder silos. The black layer greatly reduces transparency. |

Film dimensions, such as, thickness and width, and roll length sould be specified upon order.

Example: Dimensions specification of a film, 0,15 mm thick and 12 m wide, in a 60 m roll is: 0.15x12x60

The Table below indicates the highest roll lengths with thicknesses and widths of TVK-HELIOFOL films:

Width (m) | ||||||||

4.2 | 5 | 6 | 8.5 | 10 | 12 | 14 | 16 | |

Thickness (mm) | Length (m) | |||||||

0,060 | 1000 | 820 | 680 | 480 | 410 | 340 | – | – |

0,090 | 400 | 360 | 300 | 220 | 180 | 150 | 130 | 120 |

0,120 | 300 | 280 | 230 | 160 | 140 | 115 | 100 | 90 |

0,150 | 240 | 220 | 180 | 130 | 110 | 90 | 80 | 70 |

0,180 | 200 | 190 | 150 | 105 | 95 | 75 | 65 | 60 |

Recommended length and width values in the Table can be deviated from on specific request.

Films are folded in two, four or einght before winding. Depending on the folding design, the following core widths are available:

Width (m) | |||||||||

Core | 4,2 | 5 | 6 | 8.5 | 10 | 12 | 14 | 16 | |

Length | Folded in 2 | 2200 | 2600 | – | – | – | – | – | – |

(mm) | Folded in 4 | 1150 | 1350 | 1600 | 2200 | 2600 | 3100 | 2350 | 2600 |

Folded in 8 | – | – | – | 1150 | 1350 | 1600 | – | – | |

The requested fold design should be specifield in the order.